Aire Serv explains that a furnace pressure switch ensures safe furnace operation by detecting proper airflow.

- The pressure switch senses negative pressure from the inducer fan.

- It closes the circuit if airflow is correct, allowing ignition.

- If airflow is inadequate, it prevents furnace startup for safety.

Your furnace is a complex machine featuring many critical components that ensure optimal performance and safety. One such device is the furnace pressure switch. Learn more about this important furnace safety feature and what to do if yours acts up.

What is a Furnace Pressure Switch?

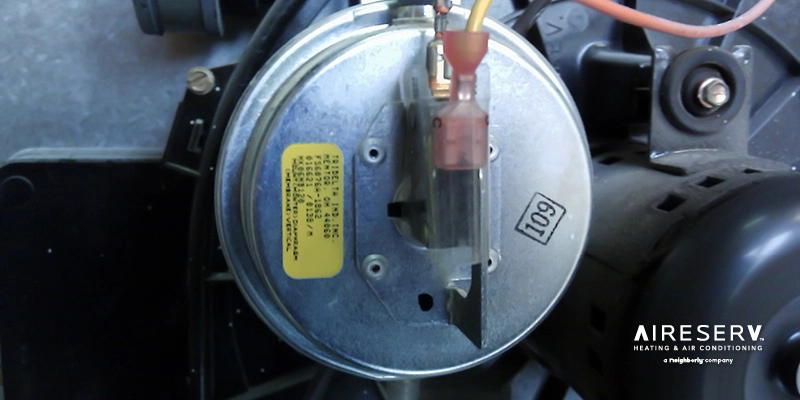

A furnace pressure switch is an automatic safety feature located near the motor. It shuts the furnace down if it senses negative pressure created by the draft inducer motor. This protects your home from dangerous backdrafting, which is when exhaust fumes are reintroduced into the system. The pressure switch also guards against gas leaks and prevents the furnace from cycling if there’s a mechanical failure.

Types of Pressure Switches

The design and number of pressure switches your furnace has depends on whether it uses conventional or condensing technology:

- A single-stage conventional furnace has one hose leading from the draft inducer fan to the pressure switch.

- A single-stage condensing furnace has two hoses on the pressure switch, one to sense pressure at the draft inducer and another for sensing venting pressure at the condensate collector box.

- A two-stage furnace may have two pressure switches.

- A modulating furnace may have three pressure switches.

Problems a Furnace Pressure Switch Can Develop

A bad switch, or a tripped switch, is a common cause of furnace malfunctions. Pressure switches may act up for several reasons, including:

- Old age, which can cause inaccurate readings and faulty furnace cycling

- Coated or stiffened pressure switch diaphragm

- Holes, tears, or other damage to the diaphragm

- Dust or dirt buildup that causes the switch to jam

Testing a Furnace Pressure Switch

If the pressure switch is damaged, this could be the reason your furnace is malfunctioning. Here’s how to check for a tripped or failed furnace pressure switch:

- Place an ohmmeter lead on both pressure switch terminals. The reading should be zero or close to zero. A high reading means the pressure switch has failed.

- An alternate method is to read the voltage between each terminal and ground with a volt-meter. The reading should be between 24 and 28 volts DC.

- Check for a clogged hose port or cracked hose running from the draft inducer motor or condensate collector box to the pressure switch. These problems can cause the switch to trip or fail.

Replacing a Furnace Pressure Switch

If you determine the pressure switch is to blame for your furnace troubles, the best option is to replace the damaged device. Here’s how:

- Turn off the furnace and flip the breaker that supplies power to it.

- Remove the combustion chamber cover (usually located on the top half of the unit).

- Disconnect the set of wires connected to the front of the pressure switch.

- Detach one or more vacuum tubes located on the side of the unit.

- Remove the screws mounting the pressure switch to the draft inducer motor and lift the switch out.

- Slide a new switch onto the motor and screw it into place.

- Reconnect the wires and vacuum tubes to the new pressure switch.

- Replace the combustion chamber panel, flip the breaker back on, and set the thermostat to call for heat. If all goes well, the furnace should operate without a hitch.

When to Call Aire Serv® for Help

If you don’t feel comfortable replacing the pressure switch, or the furnace still gives you trouble after making this repair, it’s time to call the heating and cooling professionals at Aire Serv. We’ll make sure the pressure switch isn’t being triggered and troubleshoot other parts of your furnace to ensure safe, efficient operation for the remainder of winter.

This article is intended for general informational purposes only and may not be applicable to every situation. You are responsible for determining the proper course of action for your home and property. Aire Serv is not responsible for any damages that occur as a result of this blog content or your actions. For the most accurate guidance, contact the Aire Serv location nearest you for a comprehensive, on-site assessment.

FAQs About Furnace Pressure Switches

As an industry leader and a brand that is trusted by homeowners and businesses nationwide for our knowledge and experience, we’re happy to answer your HVAC questions. Here are answers to some of the frequently asked questions about furnace pressure switches.

What does a pressure switch do on a furnace?

A furnace pressure switch, often called a draft pressure switch, is a safety component designed to prove the venting system is working before heat production begins. This is not the same component as a furnace limit switch.

The pressure switch monitors the negative pressure created by the inducer motor, ensuring proper venting of combustion gases. When the furnace starts, the inducer fan creates suction. If this suction is adequate, the pressure switch closes, allowing the ignition sequence to begin.

If the switch doesn't sense enough draft (due to a blocked vent, faulty inducer, or other issues), it remains open, preventing the furnace from firing. This prevents a dangerous buildup of carbon monoxide in your home.

How does a furnace pressure switch work?

A furnace pressure switch operates based on air pressure. When the furnace starts, the inducer motor creates negative pressure (suction) within the venting system. This suction pulls air through a small tube connected to the gas heater pressure switch. Inside the switch, a flexible diaphragm responds to this pressure change.

When sufficient negative pressure is present, the diaphragm moves, closing an internal electrical contact. This closed contact signals the furnace control board that the venting is safe, allowing the ignition sequence to proceed. If the draft is insufficient, the diaphragm doesn't move enough, the contact remains open, and the furnace won't fire.

How can I test a furnace pressure switch?

Testing a pressure switch typically involves using a multimeter to check for electrical continuity. Always ensure the power to the furnace is completely turned off at the breaker before attempting any testing. If you’re not familiar with electrical work, contact a heater maintenance professional.

- Locate the pressure switch: Find the switch near the inducer motor and identify the small rubber tubes connected to it.

- Visual inspection: Check the tubes for any cracks, kinks, blockages, or disconnections. Ensure they are securely attached to both the switch and the inducer motor or combustion chamber port.

- Disconnect a tube: Carefully remove one of the rubber tubes from the pressure switch.

- Set up the multimeter: Set your multimeter to the continuity testing mode (often indicated by a diode symbol or an audible beep).

- Test for the "open" state: Place the multimeter probes on the two electrical terminals of the pressure switch. With the inducer motor off and no suction on the switch, the multimeter should show an open circuit (no continuity or a very high resistance).

- Simulate pressure: With one tube still disconnected, gently and briefly suck on the open end of the tube connected to the pressure switch. This simulates the negative pressure created by the inducer motor.

- Test for the "closed" state: While maintaining suction, check the multimeter again. It should now show a closed circuit (continuity or a very low resistance), indicating that the diaphragm inside the switch has moved and closed the electrical contacts.

- Release suction: When you release suction, the multimeter should revert to showing an open circuit.

- Repeat for multiple cycles: Perform this suction test a few times to see if the switch consistently opens and closes as expected.

If the switch doesn't change its continuity state when you apply and release suction, or if it shows continuity even when no suction is applied, it is likely faulty and needs to be replaced by an HVAC service professional.

How do I know I need a pressure switch furnace replacement?

Indications that you may have a faulty pressure switch furnace include:

- Frequent cycling: The furnace repeatedly turns on briefly, then shuts off. This often indicates the switch can’t detect suction consistently.

- Furnace won't ignite: The inducer motor may run, but the furnace fails to light. A faulty pressure switch might not be signaling the control board that venting is established.

- Blower runs but no heat: The blower pushes air, but it's cold. The pressure switch might be preventing the burners from firing.

- Visible damage: Cracked hoses connected to the switch or a physically damaged switch housing are clear indicators of a problem.

- Failed continuity test: When tested with a multimeter, the switch doesn't show the expected open/closed behavior when the inducer fan is off/on, respectively.

If the pressure switch passes these troubleshooting tests, there may be another reason your furnace isn’t working.

Where is the pressure switch on a furnace?

The pressure switch on a furnace is typically located in the vicinity of the draft inducer motor (this is the small fan that starts before the burners to vent combustion gases). Look for a small component made of metal or plastic with one or two rubber or plastic tubes connected to it. These tubes sense the air pressure created by the inducer motor. The switch itself will also have electrical wires connected to it, but following the tubes from the inducer motor is often the easiest way to locate the pressure switch.

How to fix a furnace pressure switch?

Fixing a furnace pressure switch often involves troubleshooting related issues rather than repairing the switch itself. Here's what you can do:

- Check the tubes. Ensure the rubber tubes connected to the switch are free of kinks, cracks, or blockages. Clear any obstructions carefully.

- Inspect the vent. Examine the furnace vent pipe for any visible obstructions like debris or bird nests that could impede airflow.

- Clean the inducer motor. Dust and debris buildup on the inducer fan can reduce its efficiency. Gently clean it after turning off the power.

- Ensure proper condensate drainage. A blocked condensate drain can sometimes affect draft pressure.

If cleaning the tubes doesn't resolve the issue, the switch itself may be faulty. Replacement is usually the recommended fix for a malfunctioning pressure switch. Ensure you get the exact replacement part number, as incorrect switches can lead to unsafe operation. Due to the safety-critical nature of this component, it's often best to consult a qualified HVAC service professional for diagnosis and replacement. Regular furnace inspections and maintenance can help ensure safe and consistent operation.